ABS

From: $49.60 / kg

Compatibility:

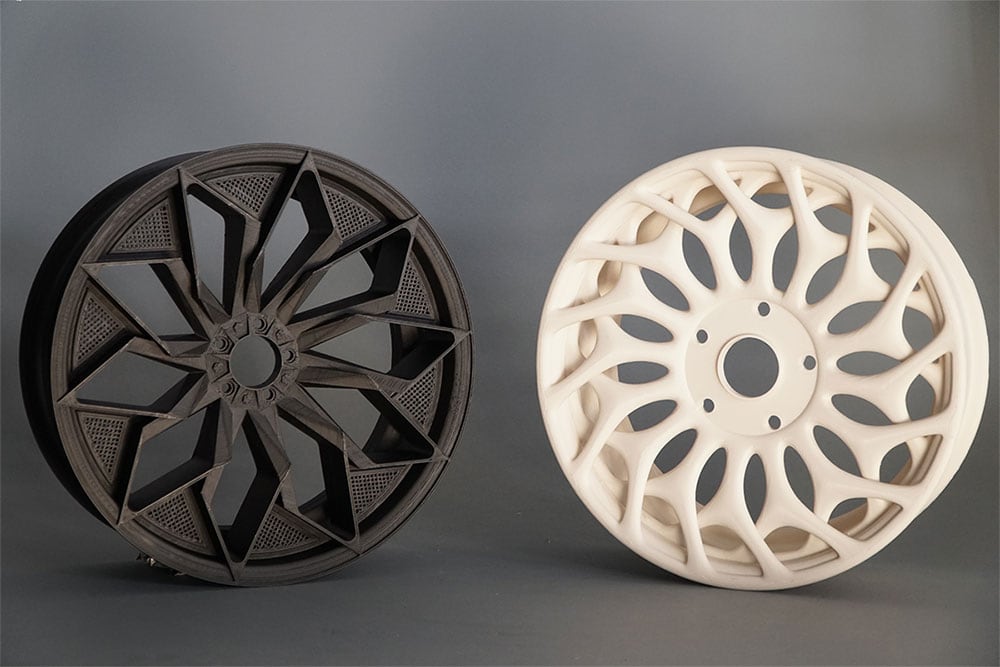

BigRep’s ABS material is a classic FFF filament that enables the production of a wide variety of products in large-format additive manufacturing. A familiar automotive manufacturing material now specialized for industrial AM, BigRep ABS is a high-strength filament suitable for mobility and a variety of white-goods and consumer appliances.

BigRep ABS has been optimized for large-format additive manufacturing and is able to print complex, ready-to-use parts including end-use, factory tooling and functional prototypes with demanding geometries.

Highlights:

- High impact strength

- Easy post-processing

- Excellent adhesion

- Minimal warping

- High heat resistance

Hands-on Review

ABS has superior impact resistance so it’s commonly found in automotive applications. It’s good in the heat too, with a heat deflection temperature of 195°F. And with a tensile strength of 30MPa, it’s strong enough for many end-use applications. ABS prints at a higher temperature than most materials and an enclosed build chamber is recommended to prevent warping, making it a bit more difficult to print than something like PLA.

Cameron Naramore – 3dprinting.com

Cameron is a 3D printer and CNC operator. He’s fond of cooking, traveling, and science fiction.

Physical properties:

| Material | Acrylonitrile Butadiene Styrene |

| Filament Sizes | 2.3, 4.5, 8.0 kg |

| Diameter | 2.85 mm |

| Density | 1.08 g/cm3 |

| Flexural Modulus (ISO 178) | 1350 MPa |

| Tensile Strength (ISO 527) | 30 MPa |

| Tensile Modulus (ATM D638) | 1400 MPa |

| Impact Strength, notched | 35 kJ/m² |

| HDT / B (ISO 75) | 91 °C |

Recommended printing conditions:

| Nozzle Temperature | 220 - 240 °C |

| Print Bed Temperature | > 60 °C |

| Environmental Temperature | n.a. |

| Printing Speed | > 40 mm/s |

CAUTION: To ensure constant material properties and printability the filament should always be kept dry.

Related products

Spares & Accessories

Filaments (FFF / FDM)

Deutsch

Deutsch